There are a LOT of online retailers when it comes to wet shaving, but there are only a few we can recommend fully and without hesitation. Above the Tie is one of those sites, and that’s why we’re so thrilled about today’s post: we got to interview Stan, owner of Above the Tie, and pick his brain about how he got started, how he makes his products, and how to choose the right wet shaving gear for your own best shave.

Thank you, Stan, for talking with us—we learned a great deal, and readers, be sure to check out Above the Tie! Stan’s self-made razors—the Atlas, the Kronos, and the Colossus, which we discuss below—are absolutely incredible, and we can’t recommend them enough.

OK, let’s dive in:

Q: Today we’re speaking with Stan of Above the Tie, a wet shaving company based out of Kingsport, Tennessee. Stan, can you tell us a little bit about yourself, and about Above the Tie?

A: Thank you, Matt, it’s good to talk with you. I was born in Tennessee and grew up in Virginia, and we lived in the country near my grandparents’ farms. My dad was a WW2 vet and my mom a stay-at-home mom. Life was pretty simple, but I was surrounded by friends and family that were all gifted in one way or another and possessed a certain degree of self-reliance. Looking back, I believe they had a much bigger influence on me than I realized. I was the first in my family to complete college—I have degrees in Radiology and Business Administration—and I began in health care as a part-time staff member working the graveyard shift and worked my way up to become Assistant Director to a Level One Trauma Center. After thirty-some years in Health Care, I can say it was an enlightening experience. At one time there were over 140 people under my supervision, and that was quite a change for someone who grew up exploring the woods, wading the creeks, and swinging on an occasional wild grape vine.

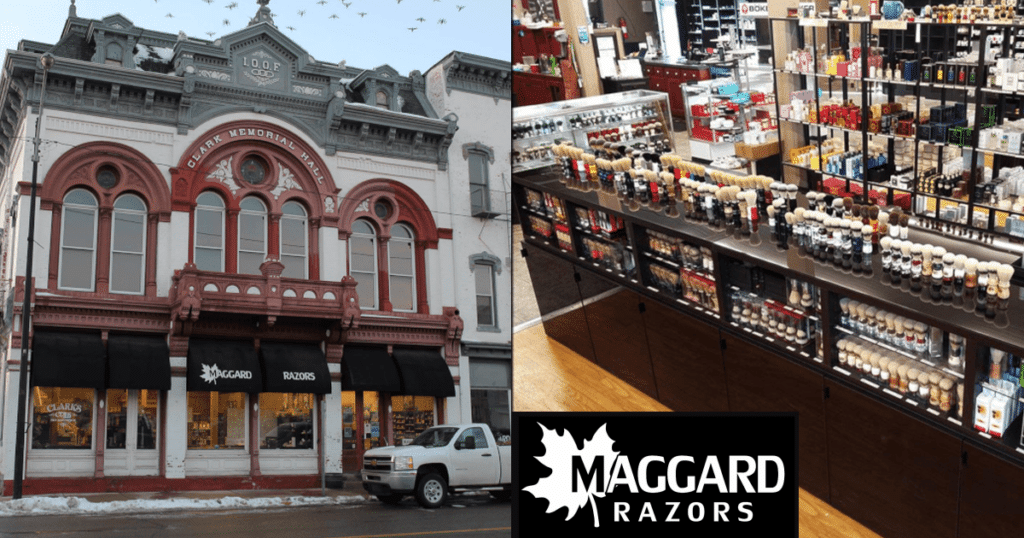

My adventure into the razor world started in 2009. After discovering the world of traditional wet shaving, I accumulated a few DE (double edge) razors. You all know how that is. After a time, I decided to sell the razors not being used, so for the first time ever, I listed items on eBay. To my amazement they sold for a profit, and that experience would lead to the birth of Above the Tie.

Q. One of the missions of Above the Tie as a company is to change the perception of shaving from a chore to a pleasure. A lot of our readers are new to wet shaving—can you describe what wet shaving is, and why it’s so enjoyable?

A: My first memories of someone shaving was watching my dad and his Gillette Super Speed. In the early seventies, though, he, like many others, changed to cartridges because of “convenience.” In time, I too started using cartridge razors with the usual shaving goo from a can. The razors were hard on my skin and often gave me razor burn and the shaving cream was about as protective as tap water. That was all I knew, though. Years went by, and frustrated by the ever-growing expense of cart razors and the often-painful experience of shaving in general I began looking for another way. I discovered wet shaving during an internet search. Quickly a whole new world opened up relative to men’s grooming and especially shaving. I was fascinated to know that DE razors were still around and actually quite common outside the U.S. The abundance of creams and brushes and other accessories made it clear that I had been living in the dark ages of shaving for far too long. Of course, I started reading and trying this new way (actually old way) of shaving, and I was amazed at what I had been missing.

For me there is nothing like using a hefty precision-made razor. One that oozes quality, craftsmanship, and history, and glides across your face providing an unequaled shave—one that leaves your face silky smooth. Add to that the quality creams leaving your skin moisturized and healthy. There is no question for me that wet shaving is vastly superior to my previous shaving efforts. No more scratchy cart razors and no more chemical goo from a can. I use a quality razor, a natural hair brush and an artisan made cream with ingredients I can pronounce. My shave is Zen-like, less expensive per shave, and I put less stuff in the landfill. I wanted others to have easy access to this same experience, and Above the Tie was born to enable more guys to change their shaving from a dreaded chore to a pleasure. I like to think we have succeeded in doing that for our customers.

Q: Customizable safety razors is a great idea, and as far as we know, you’re one of the only companies that makes them. Where’d you come up with the idea? And can you walk our readers through the process of customizing a safety razor on Above the Tie?

A: From my experience with using vintage Gillette razors (this morning I used a Gillette Toggle re-plated in rhodium), I knew various razors were more aggressive than others by design. For example, Gillette rolled out their color-coded Flare Tip Super Speed series in the 1950’s. The blade gaps were modified to give a certain degree of efficiency. The Blue Tip was the mildest with the Red Tip being the most aggressive. The regular nickel-plated Flare Tip was considered the mid-point of the razor series. Once I decided to design our own line of stainless razors, I knew I would have to address this same need. The challenge was, how could I do it without requiring the customer to purchase an entire razor for their different needs? I thought of Henry Ford’s use of interchangeable parts and my own Dad’s tool box. I wanted our customer to be able to customize a razor for themselves. They would be able to select a model with a certain handle and the base plate with the blade gap most suited for them. If they wanted a daily razor, they can choose the Atlas M1. It has our shortest handle and mildest plate. However, if they wanted to also have a more aggressive razor for those times when their beard has a few days growth, they could simply purchase the R plate and replace the M plate for that use. The plates were like the sockets with my Dad’s socket wrench. Use the same handle and interchange sockets as needed for tightening or loosening screws of different sizes. We also sell our razors in sets so the customer can have three different base plates. The R plate for regular shaving, the H plate for those multi day growth beards and finally the M plate for mild shaving or for a quick touch up before going out for the evening. Any of our handles will fit any ATT (Above the Tie) head. Also, we use a modern standard thread so our heads and handles will fit most other razor brands. It is all about making a flexible, customizable product for maximum enjoyment and efficiency.

Q: You offer some incredible models, including the Kronos, the Colossus, and the Windsor (great names, by the way). Can you tell us about each of them, and why they’re unique?

A: The Atlas 3″, Kronos 3.5″ and Colossus 4″ are the names of our early handles that match the finish of our original razor head design. The original head design has a larger blade exposure which gives the blade more flex which results in more audible feedback. This is helpful in finding your shaving angle because you can better hear the blade cutting your beard during the shave. These heads also allow the blade tabs to extend beyond the ends of the cap about 1mm on either side of the head. This early Gillette design feature allows a better grip when you are sandwiching the cap, blade, and base plate together before attaching the handle.

The Windsor Head has a different head design. Since these razors are polished, I decided to cover the blade tabs by extending the cap. In addition, I reduced the bladed exposure (not to be confused with blade gap) to make the blade more rigid. A more ridged blade gives a different shave experience—much like a single edge razor will do. By the way, I was inspired to use round ports for lather vents on the base plates after seeing the four grouped exhaust vents on my friend’s Corvette.

The Copper Windsor is of course made of copper and is coated in a marine grade clear coat so it will keep its shiny appearance. The Copper Windsor razor should not be polished or soaked in a harsh chemical bath as this may cause the clear coat to look cloudy.

Q: Many of our readers are new to wet shaving, and they’re unfamiliar with the term “aggressive.” Can you define that for us, and why a man might want an aggressive safety razor?

A: Sure! If you use a mild razor, but have a thick coarse beard, it will require many passes for the razor to remove the beard to an acceptable level. These additional passes with the too-mild razor will result in a good case of razor burn. This is why it is important to match the correct level of razor aggression to the type of beard you have. On my face, the razor with the correct aggression level will give me very nice results in three passes. A mild razor will not do this for me. However, if the razor is too aggressive, I will start to experience razor burn after a couple of shaves. Think of it this way: the aggression level is how abrasive the razor will be on your face. This is not to be confused with efficiency—an efficient razor will be well suited to your skin and beard type and will remove one’s beard with the least amount of discomfort.

Aggressiveness is just one part of the equation, though. There are a number of factors that will impact your shave. Good shaving soap is one. I like the ones with tallow, but that’s me. There are a lot of good ones out there, and the good ones should provide a good cushion and slickness to protect your skin. Also, your shaving technique is very important. Here is a good bit of advice I got a long time ago: very often, razor burns and weepers occur because you are using too much pressure, and not because your razor is too aggressive. Shaving should be a process of gradual beard reduction—so let the razor do the work! If you are having trouble with your shaves, try holding your razor with only three fingers. Using your thumb, pointer and middle fingers, hold the razor handle like a dart. This method will help in reducing any pressure you are placing on your face. Let the razor glide across your skin. After using the three-finger technique for a time, you should feel the improvement.

Q: You’ve actually got a few razors that are very aggressive—can you describe those to us?

A: There are variables, but basically the aggression of any razor is determined by the blade gap. This is the distance between the cutting edge of the razor blade and the safety bar. The wider the gap is, the more aggressive the razor. And remember—what is aggressive to one person may not be to another.

For example, our mildest base plate is the M. On my face, it’s too mild. I might as well try to shave with the edge of a credit card. However, many love the mildness this plate provides due to their particular skin and beard type. In contrast, I do not enjoy our H plates and some early vintage Gillettes, because they become uncomfortable on my face after a few shaves.

Q: On the Above the Tie website, you have a drop-down category titled “My Beard,” where you split up the razors you sell by the purchaser’s beard thickness (Fair Hair / Average Hair / Thick Hair). That’s a very helpful tool, because men aren’t always sure what razors to buy, and that provides a little guidance. Can you tell us the qualities of a razor that would make it good for a person with fair hair vs. average hair vs. thick hair?

A: The “My Beard” drop down was my son-in-law, Matt’s, idea. I believe it has been a great help for guys trying to determine what razor and base plate to choose.

In trying to determine a man’s beard type, I jokingly ask a few simple questions. If your beard is thin, and, perhaps, patchy, you will fall in the mild classification. If you can skip a day of shaving and no one notices a change in your appearance, then you have a mild beard. If, however, your beard is very thick, you get 5 o’clock shadows at noon and skipping one day of shaving makes you look like you have been on a deserted island for a week, then you are in the heavy beard category. If you fall between these two designations, then welcome to the average beard club. I’m a member of this group.

The razor for a mild beard will have a small blade gap, and you’d consider the ATT M plate or a vintage Gillette Fat Handle Tech razor. For a medium beard, go with an ATT R plate or a vintage Super Speed, and for a heavy beard, you’d require Above the Tie H plates or a vintage Gillette Red Tip. The H plates have the largest blade gaps.

Remember, though, this is a guide, and my examples are razors I am most familiar with. Hope this helps.

Q: We’ve actually gotten a lot of email from readers who are interested in starting their own businesses—either making soaps, or shave oils, or shaving brushes—and they’re not sure where to start. Can you tell us how you started Above the Tie, and the challenges you faced? Any guidance you can provide would help a lot.

A: You may be surprised to learn that Above the Tie began as a retailer of shaving supplies. We had no products of our own. I added vintage re-plated razors and vintage razors in original condition. It was later on that I designed our first stainless razor—the “Titan”. The name was later changed to “the Kronos” after a possible brand-infringement issue.

I was also able to offer a new “service,” if you will. Because our razors are made with interchangeable parts, we can exchange a plate if it’s too aggressive or too mild. Customers love the assurance that we will work with them to ensure they get the best razor to meet their needs. I’ve learned in business that you have to be open to what customers want—and they will tell you what they want if you take time to listen. Many of our products are the result of customer input.

Once I decided to design razors, I had to find a machine shop to machine them. I was told “no” many, many times. Just remember someone will eventually say, “yes.” You just have to work through the “no”s to get to a “yes.”

So, during negotiations with the owner of one of the machine shops, he expressed his concern about the risk he was taking. I knew this was about money, so I told him that I would eliminate his risk—I explained to him that it was my intention to pay cash for the entire production run. It would be entirely up to me to sell them. With that, his entire mood changed, and the deal was made. I had a professor in business college who would say “cash is king,” and that interaction provided that he was correct.

Speaking of cash, by the way—I have always run a cash business. What I mean by that is that ATT has never had any debt, and I would encourage other business owners to do the same. You don’t want to lose sleep at night because you burrowed a bunch of money for a venture that you are not sure will succeed.

I know a lot of well-known suppliers in the wet shaving world, and I believe I can share some traits that they all have that helps them to be successful. Here are the big ones:

Treat others the way you want to be treated. This truth needs no explanation, really.

Offer great service. Your customers are giving you their hard-earned money, and if you cannot provide great service, next time they will buy from someone else.

Don’t argue with your customers. In the age of social media, you will never win.

There is a cost of doing business. Sometimes items will get lost in the mail, etc. You will have to eat the loss and send the customer another package. It happens.

Don’t sweat the small stuff—and most stuff is small.

When I committed to make our first stainless steel razor, I posted on a large shaving forum explaining what I was doing. I also wrote that I would need volunteers to try the razor and provide feedback. A number of guys quickly offered their services. After selecting the “testers,” I mailed a sample razor to each of them. A week later, they provided very positive feedback. Members of the forum started reading and responding to threads these same testers generated concerning their experiences with this “new” razor. Needless to say, the “buzz” generated among a very focused group of potential customers was very strong. I did not initially realize what was occurring, but it was soon clear that based on very positive posts about this new razor, a customer base and demand was created before the first razor was ever sold.

I believe if you want to get into soap-making or brush-making, you should do so. Be creative and original. To be honest, as a consumer myself, I like shaving soaps with tallow and I think most of them smell lame and boring. Perhaps you’re the person to change that! I think you should smile when you smell your shaving cream in the morning.

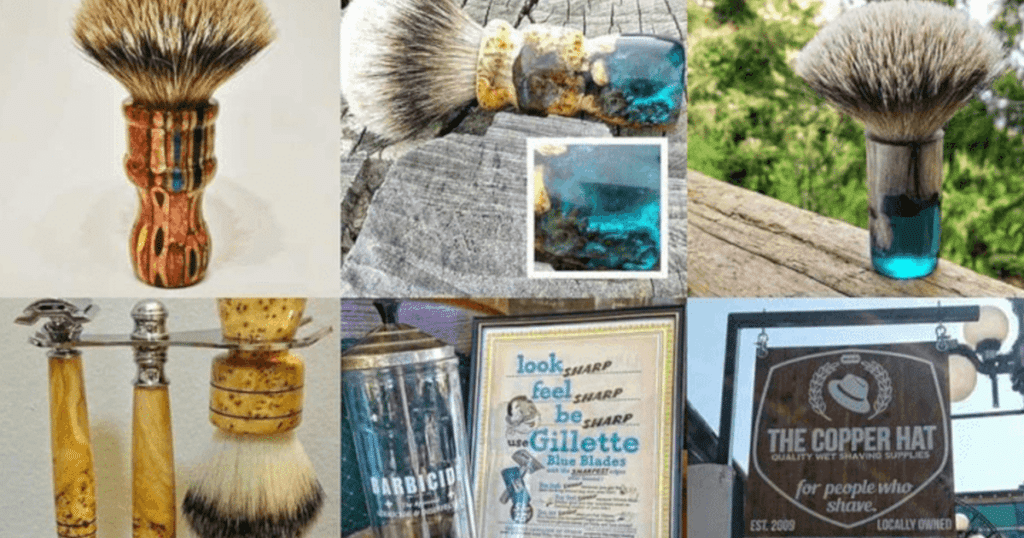

As for brushes, I would like to see handles with classic design but clever materials. I would like to see mixed mediums such as resins and woods. Why not use mastodon tusks or scrap aluminum from a fighter jet? Maybe you could use material from a race car. Surprise me!

I hope sharing a little of my start-up experience will be both informative and useful to anyone wanting to start their own business. If you have the desire, are willing to do the work and sacrifice the many hours, then by all means try. If you don’t, you will always wonder what would have happened if you had just taken that first step. I am glad I did! It certainly changed the life of this country boy.

Q: There’s a been a renewed interest in wet shaving over the last decade or so—why do you think that is?

A: For me, it had to do with the expense of disposable multi-blade razors and the poor performance they provided. They started giving me such bad razor burn, on my neck especially, that I gave electrics a try. The electric shavers were no better, and even more expensive. The tipping point came for me when I went to purchase a package of refill heads for my Gillette Mach whatever-it-was and the price was $40.00. I remember thinking, “There has to be a better way.” Later that day after some internet searching, I discovered—or I should say, rediscovered—wet shaving or traditional shaving, and I never looked back. I believe many have walked this same path and made the same discovery—if you look, you might start to see DE razors and/or shaving brushes and soaps in TV commercials. They may be sitting in the corner of the shot, but they’re there. The placement and/or inclusion of anything in a TV commercial or movie will be seen by many eyeballs, and in my opinion, this has had an impact on consumers. They are informing customers that not only are these products available, but that they’re cool to use. I actually just saw a luxury car commercial that begins with a popular movie actor lathering up with a shaving brush and soap. The commercial is all about being “classy,” and it starts out with wet shaving.

Q: Last but most certainly not least, where are your products made?

A: Our razors are 100% made in the USA! We use two machine shops to make our stainless and aluminum razors—one is located here in Tennessee, and the other is in Pennsylvania.

Q: Stan, that about wraps it up for us—thank you so much for the time you spent with us!

Readers, go over and check out the razors at Above the Tie—we’re big fans, and the site is easy to navigate and use. Stan, thanks again!

Michael Morris is the head writer here at Rough and Tumble Gentleman. He's got a ducktail beard and loves Brazilian jiu-jitsu. He's married to the woman of his dreams and lives in Brooklyn, NY.